Todays work consists of one pipe as it took

me most of the day to do it . Art Ruppelt, of Ming-Kahuna Tampers, sent

me a very unusual Tom Eltang pipe to see if I d be interested in trying

to make. It s called a ukelele.

My initial comment was that if you chewed thru the stem on this pipe you d be in big trouble as the briar end of the shank is the stem. Art assured me that other models of the ukelele by TE and others incorporated a regular bit. Here is an Ed Burak version of the same shape:

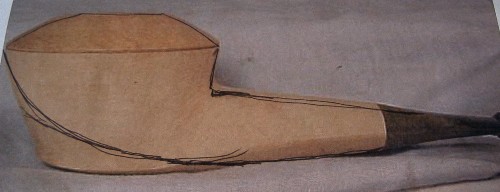

Art supplied me with some dimensions which are difficult to believe. The pipe is almost 2.5" wide! Under 1.5" tall and a little over 5" long.Pretty tight for all that s happening. One thing I completely missed is that the shank is actually wider than the bowl. I started off with a pretty nice piece of briar. I lathed the top and put the line in and did some rough shaping and got stuck and had to take some pix and ask Art for some advice.

I realized this was nowhere near the original . Art did some drawing in photoshop and sent me back this with the following instructions:

Here's my thoughts as shown on my drawings on your photo. As far as an Eltang

copy, the general profile of the pipe is high. On the Eltang there is

actually very little side profile. But, this is your version of a uke, so it

need no be exactly like the Eltang. Depending how deep your bowl is cut you

could lower the overall profile of the pipe by swooping up to the front as

I've drawn here. Of course, if your bowl goes deep you are limited. Also,

my lines go to the bottom of the shank which doesn't take into account your

shank side contours, but that could be worked out somehow?

BTW, I'm also having a hard time figuring the front of the pipe. If you can

swoop it up like I've shown and then bring the shank side contours up around

the bowl's side midline that could work.

As to the shank, with your version the shank width is narrower than the bowl

width. With the Eltang the shank widens out to the same width as the bowl

diameter (almost). Your variation is fine. But, the shank should have a

narrower (top to bottom when viewed from the side) profile doing nothing to

take away from the shank width when viewed from above. Make sense? But,

taking material away from the top of the shank to accomplish this will raise

the bowl profile and the pipe looses its low profile looks. So, taking

material from the bottom of the pipe (which is consistent with shaping the

bowl as I discussed) will narrow the top to bottom profile of the shank and

be consistent with the swoop at the bowl front in my diagram (if that swoop

is possible).

He then sent me the following directions along with this pix:

Also, your shank/stem tends to fishtail out. I'd prefer to see the shank

contours bow out to the end of the stem. Your stem/shank contours when

viewed from above have contours that are convex, meaning that they bow in.

I'd like to see.. Here, I've attached a drawing, the one with the star is the

idea. Maybe you have enough room with the stem you're using to accomplish

this. You could also accomplish this by shortening the stem. Remember, I

don't need much of a button (if any at all) as I don't clench a pipe. A

shorter stem would be fine to accomplish this profile as I have in the

attached drawing. Also, this is a pocket pipe, so any reduced length is only a plus.

BTW, the top of the shank should be as flat as possible with a nice bow

upwards towards the center line. Same with the bottom. A shank

cross-section like this: () if not even a bit flatter.

I had a lot to think about and trying to follow his instructions as best I could with the wood I had left I made the following:

Well , luckily for me he liked the variation and accepted the pipe. Here are his words:

The size of the pipe is perfect and will make a perfect pocket pipe. If you

ever do another version of this shape I'd be interested in it, but for me

this pipe is perfect. Its your version, and its damn good

especially considering working from photos must be a bear. Its damn good,

period. I couldn't imagine trying to duplicate a complex shape like that

from three photos that are far less than optimal. As far as I'm concerned

you've kicked ass on this pipe.

I hope you share this pipe with others as this is a wonderful piece that I

believe will be much sought after with future requests. The side profile of

the pipe is extra nice, and the bottom shank to bowl contours are super.

And, the grain speaks for itself! Very, very nice.

Thanks so much for your efforts. IMHO you are to be congratulated!

Best,

Art

Well this goes to show you how nice pipe people can be. I didn t get it "right" but Art went with it. It was a pleasure to work with a artisan like Art. Anyone who has seen his tampers will know what I mean!

| 1/14 | 1/21 | 1/27 | 2/2 | 2/7 | 2/14 | 2/28 | 3/1 | 3/2 | 3/5 |

| 3/6 | 3/7 | 3/8 | 3/16 | 3/21 | 3/28 | 3/29 | 3/30 | 4/4 | 4/8 |

| 4/9 | 4/10 | 4/11 | 4/12 | 4/13 | 4/13 | 4/14 | 4/17 | 4/20 | 4/22 |

| 4/23 | 4/24 | 4/25 | 4/29 | 5/15 | 5/17 | 5/26 | 5/29 | 6/2 | 6/7 |

| 6/8 | 6/14 | 6/15 | 6/26 | 6/28 | 6/30 | 7/2 | 7/5 | 7/16 | 7/17 |

| 7/18 | 7/22 | 7/26 | 7/27 | 7/31 | 8/1 | 8/2 | 8/3 | 8/7 | 8/8 |

| 8/10 | 8/11 | 8/14 | 8/16 | 8/16 | 8/17 | 8/20 | 8/22 | 8/24 | 8/28 |

| 8/31 | 9/3 | 9/4 | 9/6 | 9/10 | 9/16 | 9/18 | 9/19 | 9/20 | 10/11 |

| 10/12 | 10/16 | 10/19 | 10/20 | 10/22 | 10/23 | 10/26 | 10/27 | 10/29 | 10/30 |

| 10/31 | 11/3 | 11/11 | 11/14 | 11/17 | 11/20 | 11/21 | 11/22 | 11/25 | 11/27 |

| 12/2 | 12/8 | 12/13 | 12/14 | 12/17 | 12/19 | 12/21 | 12/22 | 12/25 | 12/29 |

| 12/30 | 1/2 | 1/3 | 1/4 | 1/5 | 1/8 | 1/9 | 1/11 | 1/12 | 1/13 |

| 1/14 | 1/15 | 1/16 | 1/17 | 1/18 | 1/20 | 1/21 | 1/23 | 1/25 | 1/26 |

| 1/27 | 2/2 | 2/4 | 2/5 | 2/7 | 2/8 | ||||